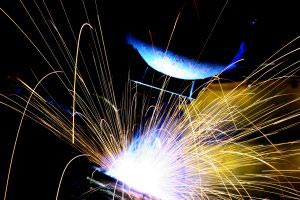

Welding is a challenge when it’s done in an area with FOD controls. It can be a messy process that presents ample opportunities for foreign material intrusions. To minimize the risk of contamination, a welder should practice good housekeeping, as well as employ the use of the following whenever possible.

Welding is a challenge when it’s done in an area with FOD controls. It can be a messy process that presents ample opportunities for foreign material intrusions. To minimize the risk of contamination, a welder should practice good housekeeping, as well as employ the use of the following whenever possible.

Weld Stub Buckets

Rather than leaving weld stubs around a work area, they should be stored in stub buckets. The best stub buckets for FME provide a burn-proof container with a chain tethered lid. This eliminates the possibility that the lid may become foreign material. The buckets should also be insulated on the bottom to prevent arcing.

Purge Bladders

Purge bladders reduce the amount of inert gas used on pipe welds. They seal off a space inside of a pipe and limit the flow of gas exclusively to the area where it is necessary. They are easily removable and reusable and they limit the potential of the purge dam itself becoming foreign material. They also leads to cleaner welds.

Nylon Abrasives

Nylon abrasives provide an alternative to wire brushes and are often preferred for use in foreign material exclusion zones. The broken bristles from wire brushes will typically do more damage than the bristles of similar nylon brushes. The bite of a nylon brush is less aggressive than a wire brush and can also reduce the amount of waste material scratched out of a surface.

During the welding process, or any process that could create debris, pipes and nearby openings should be covered to prevent foreign material intrusion. A number of pipe sealing options are available to close off openings.

Use our lanyard selection form and we'll help you get the right lanyards for the job.

Use our lanyard selection form and we'll help you get the right lanyards for the job.